Product overview

Dayu®CBF reactive wet-laid polymer waterproofing membrane is a self-adhesive (wet-laid reactive bonding) waterproofing membrane composed of a tire base (or surface film layer), self-adhesive modified asphalt colloid and silicon-coated isolation membrane.

l Substrate (or film): Resin film, placed in the middle of the coil is regarded as the tire base, placed on one side is regarded as the surface film layer.

l GlialSBS modifier is used to modify petroleum asphalt to improve its high and low temperature resistance, fatigue resistance and bonding performance, and to improve the bonding performance of modified asphalt self-adhesive properties (especially under wet paving process) by adding tackifying resin and other polymer hydrophilic additives.

l Surface material: Polyethylene film, silicon-coated isolation film.

Product Features

l The glue has strong bonding ability, self-healing function and excellent water tightness of nail rod. When wet paving process is adopted, the flatness of the base surface is required to be low, and it can form a molecular key combination with cement mortar to form a waterproof system with full adhesion and no water channeling, rigid flexibility and no gap.

l Cold construction (no fire), self-paste, construction efficient, safe and environmentally friendly.

l Dry paving method and wet paving method can be adopted according to climate environment and basic surface conditions. The construction method is flexible and the construction period is guaranteed.

l There is no recycled material to add, and it can be used in underground engineering with the same life span as the building.

l It can form a composite waterproof layer with other compatible coatings or coils to meet higher grade waterproof requirements.

Specifications and models

|

Bonding surface |

Single-sided Bonding (S)/Double-sided Bonding (D) |

|

Thickness |

1.5 mm / 2.0 mm |

|

Width |

1000 mm |

|

Length |

15 m / 20 m |

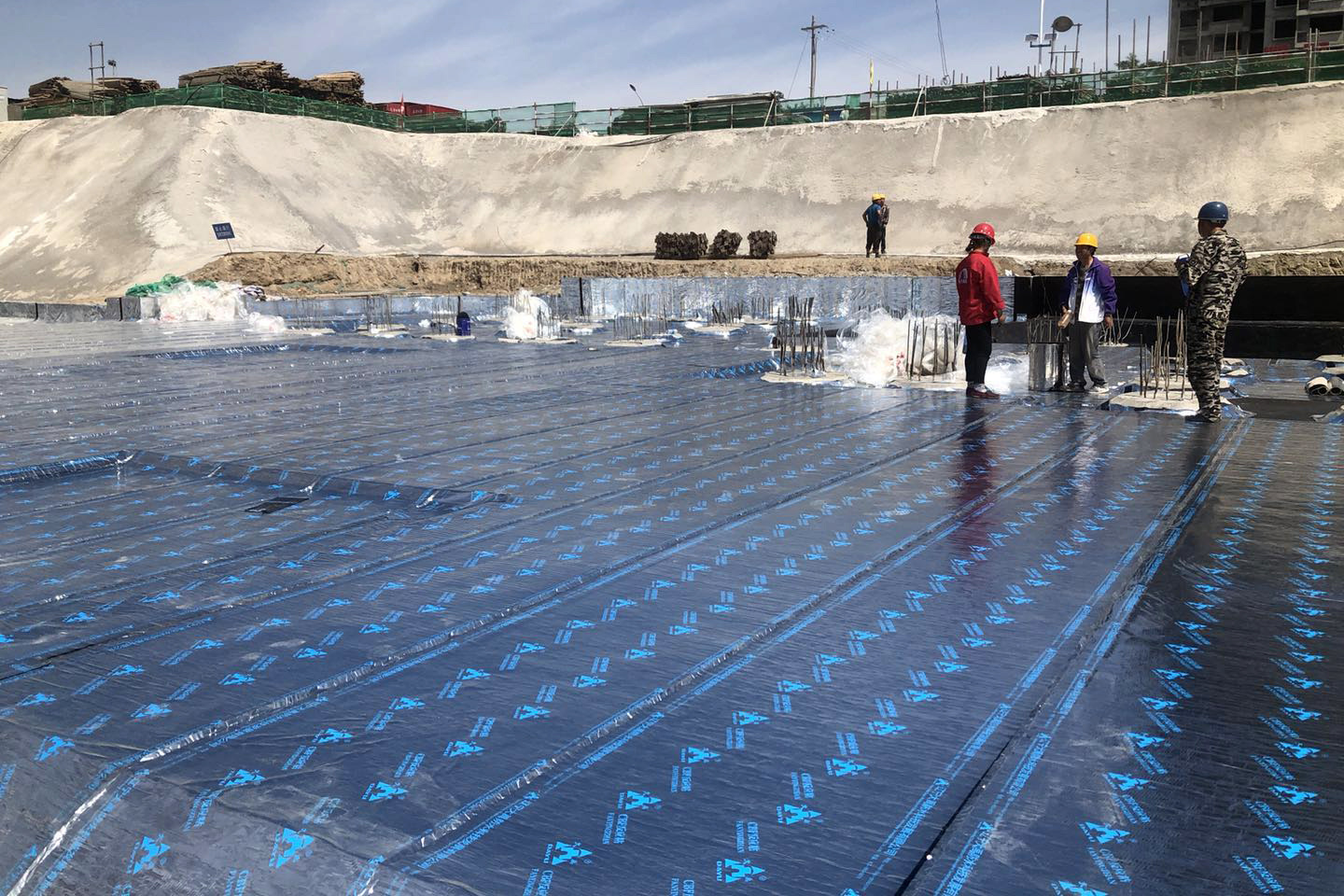

Scope of application

| Suitable for building basement, non-exposed roof and other parts of the waterproof project.

| It is especially suitable for waterproof engineering of projects with open fire prohibition and difficult drying at the grass-roots level.

Construction process

Wet spreading method

l Basic requirements: solid, no sediment, laitance, no empty drum, loose, sand and other phenomena.

l Interface treatment: wetting the base layer to a wet state without open water.

l Preparation of mucilage: according to the temperature and humidity, add clean water into the batching barrel according to the water cement ratio of 0.35~0.40, then add appropriate amount of 42.5Mpa ordinary Portland cement, and fully mix into uniform, fine and non-lumpy cement slurry. The construction of the facade should be mixed with 0.5 ~ 1% by weight of the slurry.

l Trial laying of coiled material: lay the coiled material flat on the base surface, align the elastic line or the overlapping edge of adjacent coiled material, adjust the overlapping width, and rewind after standing for a period of time to release the stress.

l Scraping glue: the glue is scraped on the base (plane) or scraped on the coil bonding surface (elevation), with a thickness of 2~3mm.

l Spreading coil: push and roll forward to lay the coil, drive the slurry and exhaust, so that the coil is closely bonded with the mucilage and the base.

l Body lapping: tear off the independent lapping film and roll the lapping edge to make the asphalt adhesive layer body bond tightly.

dry paving method

l Basic requirements: solid, dry, no sediment, laitance, no empty drum, loose, sand and other phenomena.

l Interface treatment: uniform spray (roll) coating matching base treatment agent, improve the coil and the adhesion of the base.

l Trial laying of coiled material: lay the coiled material flat on the base surface, align the elastic line or the overlapping edge of adjacent coiled material, adjust the overlapping width, and rewind after standing for a period of time to release the stress.

l Cold adhesive paving: push forward to roll the paving coil, tear off the isolation bottom film, compact and exhaust to make the coil and the base closely bond.

l Body lapping: tear off the independent lapping film and roll the lapping edge to make the asphalt adhesive layer body bond tightly.

performance index

Products in accordance with the national standard "wet waterproofing membrane" GB/T35467-2017 manufacturing.

The performance index meets the requirements of Class H coil in the standard.

|

Project |

Indicators |

|

Pull force |

≥300 N / 50mm |

|

Elongation at maximum tension |

≥50% |

|

Tearing force |

≥20N |

|

Heat resistance |

70℃, 2h No flowing, dripping, slippage ≤2mm |

|

Low temperature flexibility |

-20 ℃ No crack |

|

impervious to water |

0.3 MPa,120 min impervious to water |

Previous Page

Previous Page